Welding is the foundation of modern manufacturing, construction, and engineering. When discussing welding and types of welding, we’re exploring not just a method of joining metals but an entire field of expertise that reach industries from shipbuilding to aerospace.

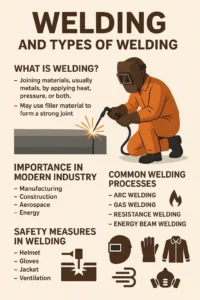

Welding is the process of joining materials, usually metals, by applying heat, pressure, or both. Welding is a broad term that covers a number of different methods and tools, each customized for a certain type of metal or use. This complete guide will cover all the main forms of welding, point out the most important differences between them, and demonstrate how new technologies like the gas metal arc welding machine are changing the way people work in factories.

Why Understanding Welding Types is Essential

Knowing the welding types helps engineers, metal fabricators, and students choose the right method for a particular application. Whether you’re building a bridge, repairing a bike frame, or working in a factory, picking the correct welding type ensures safety, efficiency, and strength.

Key Welding Processes Explained

Let’s break down the main types of welding, focusing especially on the popular techniques and tools used in the field.

Arc and Gas Welding: The Backbone of Fabrication

Two of the most widely practiced methods in the welding industry are arc and gas welding.

Arc Welding

This method uses an electric arc to melt the workpieces. It’s one of the most common welding types because of its versatility and affordability.

Main types include:

- Shielded Metal Arc Welding (SMAW) – “stick welding”; portable and suitable for outdoor work.

- Gas Metal Arc Welding (GMAW) – often referred to as gas metal welding, this technique uses a wire electrode and shielding gas to weld metals quickly and cleanly.

The gas metal arc welding machine is essential in many workshops and factories due to its ability to automate and optimized the welding process.

Gas Welding

Gas welding typically uses a mixture of oxygen and acetylene to produce a high temperature flame. It’s ideal for:

- Thin metal sheets

- Auto body work

- Plumbing tasks

Gas welding is still an important skill to learn for metal fabrication and small-scale companies, even if it is a little older than arc processes.

Welding and Types of Welding: Complete List

Here is a list of the major welding types used across industries:

| Welding Type | Method | Best For |

|---|---|---|

| Shielded Metal Arc Welding | Arc | Heavy-duty structural welding |

| Gas Metal Arc Welding (GMAW) | Arc + Shielding Gas | Fast, clean welds in automotive, metalwork |

| Gas Tungsten Arc Welding | Arc | Precision welding of thin metals |

| Oxy-Acetylene Welding | Gas | Repairs and soft metal fabrication |

| Spot Welding | Resistance | Sheet metal in auto manufacturing |

| Laser Welding | Energy Beam | Aerospace, high-precision applications |

| Friction Welding | Solid-State | High-strength, industrial machine parts |

Gas Metal Welding: Powering Speed and Precision

Gas metal welding, commonly known as GMAW, is an arc welding process in which a continuous wire electrode is fed through a welding gun. Shielding gas is simultaneously supplied to protect the weld pool from impurities.

Advantages:

- Fast and efficient

- Minimal clean-up

- Great for thin and medium-thickness metals

Common uses:

- Automotive repairs

- Metal fabrication shops

- Pipe welding

The gas metal arc welding machine makes this process semi automatic or fully automatic, allowing industries to scale production while ensuring quality.

Choosing the Right Welding Type

When selecting the best method from the many welding types, consider:

- Material: Some techniques work better with steel, others with aluminum or copper.

- Thickness: Arc welding suits thick sections; TIG or gas welding is better for thinner materials.

- Environment: Outdoor conditions may affect shielding gas welding (e.g., wind interfering with gas flow).

- Skill Level: Beginners might prefer MIG, while experts can handle TIG or stick welding.

Tools of the Trade: From Torches to Machines

Modern welding setups can include:

- Welding helmets and safety gear

- Wire feeders and electrodes

- Gas cylinders for shielding

- Gas metal arc welding machines

- Welding tables, clamps, and vices

Welding and Types of Welding in the Modern World

Understanding welding and types of welding is not just useful it’s essential. Whether you are working on a DIY project or managing a full scale industrial operation, knowing your options can save time, money, and materials.

Techniques like arc and gas welding, along with advanced tools like the gas metal arc welding machine, are transforming the way we build our world.

At A to Z Fabrication Pty Ltd, based in Guildford, NSW, we specialize in expert welding and fabrication services using state of the art techniques and machines. With a strong commitment to quality and precision, we offer customized designs for projects of all sizes. Whether you need custom metalwork, structural welding, or industrial fabrication, our team is ready to deliver excellence from start to finish.

FAQs: Welding and Types of Welding

What is welding and what are the main types of welding?

Welding is a process that joins two or more materials typically metals by applying heat, pressure, or both. The main types of welding include arc welding, gas welding, resistance welding, energy beam welding, and solid state welding. Popular techniques like gas metal welding and arc and gas welding are widely used in industries.

How does gas metal welding differ from other welding types?

Gas metal welding, also known as MIG or GMAW, uses a wire electrode and shielding gas to form the weld. It’s faster and cleaner compared to arc welding or gas welding, and is often used with a gas metal arc welding machine for efficient production in industries like automotive and fabrication.

Which welding type is best for beginners?

MIG welding a form of gas metal welding is considered the easiest to learn. It offers cleaner welds, is more forgiving of minor errors, and uses an automated wire feed, making it ideal for those new to welding and types of welding.

What are the advantages of arc and gas welding?

Arc welding is known for its deep penetration and strong joints, making it ideal for structural work. Gas welding, such as oxy-acetylene welding, is portable and effective for thin metals and repairs. Both methods are foundational in the study of welding types.

What is a gas metal arc welding machine used for?

A gas metal arc welding machine is designed for MIG/GMAW welding. It automates the welding process by continuously feeding wire and shielding gas, allowing for faster, cleaner welds. It is commonly used in manufacturing, shipbuilding, and auto industries.

Can I use gas metal welding outdoors?

It’s not ideal to use gas metal welding outdoors without protection. The shielding gas can be blown away by wind, leading to contamination and weak welds. For outdoor jobs, flux cored arc welding is a better alternative.